Power To The People

The post-consumer glass recycling scheme developed by integral blinds manufacturer Morley Glass in conjunction with Saint-Gobain Glass has now saved enough...

Read Full Article

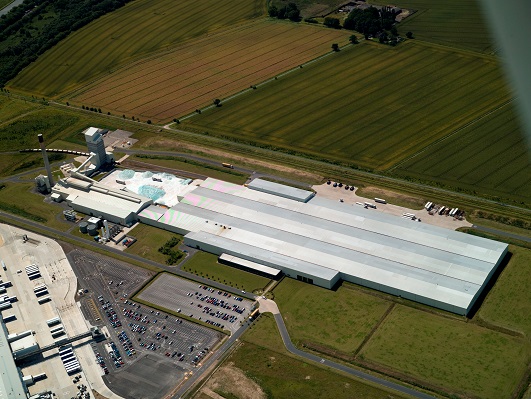

Guardian Glass is kicking a huge investment into its Goole production facilities to increase its ability to supply float glass, primarily to the UK and Ireland, while also improving the plant’s energy efficiency.

The cold tank repair, which began in April 2021 and will be completed in October, will rebuild the furnace with one of the most advanced technologies available and expand the melting capacity by 20 per cent to 825 metric tons per day.

“Guardian Glass is investing in the future of commercial and residential building in the UK and Ireland. This work assures that Guardian can continue to support the evolving demands of our customers with greater capacity, efficiency and environmental stewardship.”

– Guus Boekhoudt

Executive Vice President, Guardian Glass

Cradle to Cradle Certified

"As one of the world’s largest manufacturers of float, coated and fabricated glass products and the only UK glass manufacturer with building products achieving the bronze Cradle to Cradle Certified Products Standard version 3.1, Guardian is committed to our Stewardship Framework," continues Boekhoudt. "This core principle ensures that we consider environmental, social and corporate governance priorities in our day-to-day operations as we strive to find more efficient uses of resources, continuously improve our products and services and strengthen partnerships with our local communities around the world."

Goole, East Yorkshire

The Goole facility produces a wide range of float, coated and laminated glass products. Almost 100 per cent of the solar control glass produced at the facility supplies projects within the UK.

Enhancements to the facility include:

A furnace with improved energy efficiency and increased output.

Enhanced automation to provide more reliable operations and reduce manual tasks. This enables staff members to advance their skills by taking on more challenging responsibilities.

An ongoing initiative to recycle cullet. Increasing the cullet ratio in products cuts energy consumption, reduces raw materials and reduces waste.

“Operations transformation improves efficiency and effectiveness, which boosts productivity and gives Guardian Glass a competitive advantage,” explains Goole Plant Manager Chris Duguid. “These changes are critical to demonstrate to our partners that we value them and will continue to support them with the best products and services.”

Picture: Guardian Glass' Goole, East Yorkshire plant.

Article written by John Roper

15th October 2021