The turbo advantage

Stuga Machinery has bought the Stürtz HSM 6-KV Turbo corner/transom welder to the UK. Here’s how it could increase your output by 163 frames per...

Read Full Article

Stuga, now part of Stürtz Maschinenbau, launched a newly developed transom corner cleaner, the TXR, at the 2023 FIT Show, as part of its growth strategy, UK managing director Ed Williams writes.

We spent the early part of the year developing the management and operational structure of Stuga under new owners to get it ready for growth and improve performance in all areas.

It is not so much a case of ‘all change’, rather it’s a re-ordering of roles and responsibilities to ensure we flex the muscle of our brilliant team more effectively.

The launch of the new transom cleaner represents a complete re-development of a solution that Stürtz had in its portfolio for many years. It has benefited from a total upgrade and the addition of key features to ensure we have a solution that is completely focused on the complexities of the UK market.

Capability

The TXR provides another string to our bow adding to our, already impressive, portfolio of automated solutions in welding, cleaning and logistics.

The industry knows the Stürtz brand well and of course Stuga is synonymous with sawing and machining but the TXR was a missing piece of our plan to grow Stürtz presence in the UK market. We are delighted with the warm reception we have received so far from our customers in the UK, who seem to universally welcome the idea of this solution from Stürtz as a credible alternative to current options available to them.

The right solution

The PVC-U market in the UK is dominated by complex frame and sash configurations that require efficient and reliable cleaning of transoms that often can’t be handled effectively on higher speed multi-point corner cleaning machines.

The main feature of the Stürtz TXR is an interpolating 3-axis CNC controlled cleaning head, which provides higher output and greater control over the cleaning function than that offered by conventional systems where the entire head moves.

Spring mounted knives, which follow the contour of profiles, along with automatic recognition means that the machine produces consistently high-quality product and mitigates the risk of serious machine damage that can be caused on machines where the wrong profile can be loaded by the operator.

Fabricators in mind

It was vital that we considered the production and quality challenges faced by our UK customers every day and tailored a machine designed to meet their needs. The addition of profile recognition, sprung knives and a crucial auto-shift function on the cleaning heads is delivered in a cost effective, well-engineered design.

Traditional transom cleaning solutions – indeed the old technology that Stürtz previously used – relies on moving huge masses of the machine structure from one side of the transom to the other to complete the cleaning task. We wanted to eradicate the need to do this and focused our efforts on designing a solution that moves smaller masses in a much more precise and efficient way.

The results are fantastic with repeatable product quality and a huge reduction in the stress on the machine itself – any factory maintenance engineer understands the benefit in reducing the mass you want to move and its impact on machine reliability.

Ready to deliver

The transom corner cleaner is a staple asset for every PVC fabricator in the UK and with our after sales team of 11 field-based technicians and a slick, reliable and well-engineered machine, it’s clear to see that the future for Stürtz and Stuga in the UK is bright.

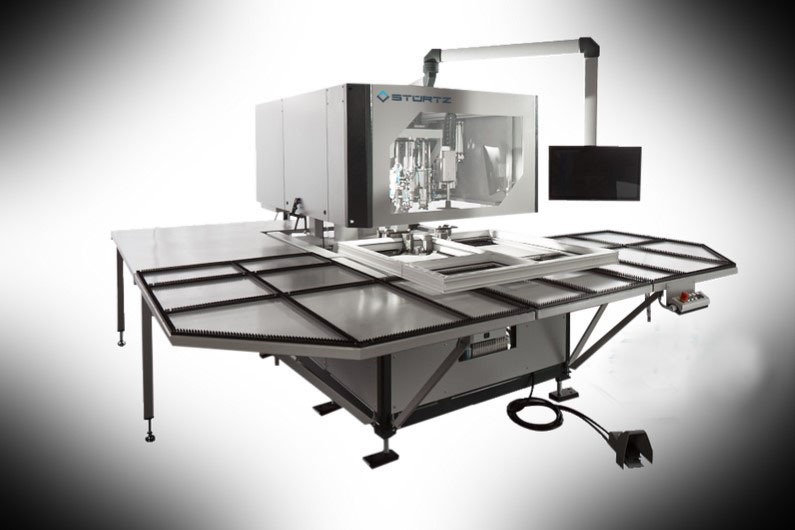

Picture: Stürtz and Stuga’s new TXR transom cleaner.

Article written by John Roper

01st June 2023